This equipment is developed for high-end wine cap technology, and can print up to 8 colors + 2 colors of hot stamping twice. The bus servo industrial control system and the dual visual positioning system are more accurate in color registration, and can easily achieve multiple uses of one machine, saving equipment procurement costs and human resources for customers to the greatest extent.

JY-516P Fully servo bottle cap 4 printing 1 hot stamping CCD vision positioning production line

一. Equipment features:

This equipment is developed for high-end wine cap technology, and can print up to 8 colors

+ 2 colors of hot stamping twice. The bus servo industrial control system and the dual visual

positioning system are more accurate in color registration, which can easily achieve multiple

uses of one machine, saving equipment procurement costs and human resources for customers

to the greatest extent.

二, Technical points and process flow of the equipment:

① Pour the workpiece to be screen-printed into the hoist storage hopper manually, and the hoist

automatically lifts it to the material sorting tray;

② The material sorting tray automatically sorts and selects the material to the storage track, and

then sends it to the feed slide rail of the printing machine after positive and negative identification

vand selection, and rolls and slides to the feeding bottle tray by its own weight, and a utomatically

clamps it when sensing the presence of material;

③ The feeding manipulator automatically clamps it to the fixture shaft of the turntable, and the

fixture shaft and the printed bottle cap are slightly tight, so that it will not shift or fall at other stations;

④ The high-precision 16-station rotary turntable rotates in sequence, and performs electrostatic dust

removal, visual top feature positioning, visual bottle cap side feature positioning, and workpiece detection,

first color screen printing, LED UV ink curing, second color screen printing, LED UV ink curing, third color

screen printing, LED UV ink curing, fourth color screen printing, LED UV The ink is solidified, the bottle cap is

screen printed sideways and then hot stamped, the robot automatically grabs the material, the conveyor

belt automatically sends it out,Manual container collection inspection; (the 4 colors of printing can be matched

arbitrarily, the unused stations can be turned off, and the hot stamping is hot stamping on the screen printing)

⑤ Screen printing is automatic printing with material, and screen printing is not performed when there is no part;

the same is true for hot stamping, hot stamping when there is a part, and no hot stamping when there is no part

⑥ Automatic color printing is completed.

⑦ Cycle the above actions to achieve continuous automatic printing without stopping, and achieve the purpose

of high efficiency and high quality production.

三. Equipment appearance display:

四. Equipment details display:

五. Technical parameters of the equipment:

① Screen printing workpiece: Design according to the lid provided by the customer

Yanghe Blue Excellent lower cover, two-color screen printing

Middle cover monochrome screen printing, one printing and one hot stamping relief printing

M6 + Tibetan version middle cover printing 4 + 3 = 7 colors (secondary printing)

② Positioning mechanism: The top of the cover that needs to be positioned has features that can be

positioned (visual photography positioning). Currently, there is M6 + top side positioning;

③ Screen printing speed: Blue Excellent screen printing monochrome and two-color 45-50PCS/min;

One printing and one hot stamping 45---50PCS/min

M6 + Tibetan version middle cover screen printing 45--50PCS/min.

④ Printing color accuracy: ±0.10mm

⑤ Power supply: 3∅380V 50HZ 20.5KW

⑥ Air supply: 5---7bar

⑦ Machine dimensions: 3820mm * 2640mm * 1980mm

⑧ Area occupied by the machine during normal operation: 5200mm * 3800mm*2200mm

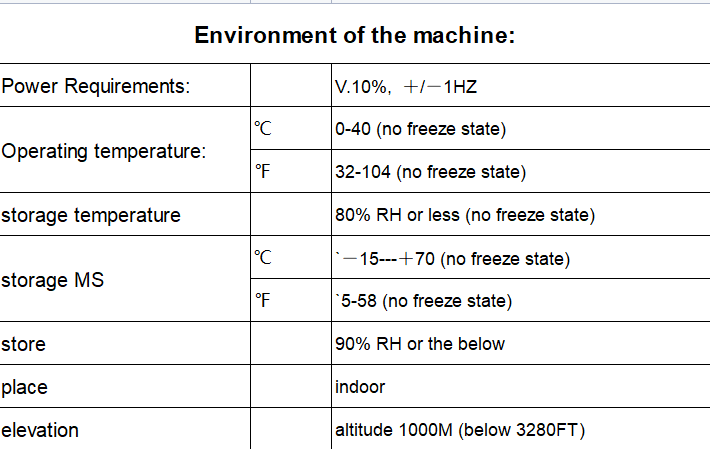

六,the storage and use environment of the equipment:

七, the scope of application of the product:

![]()

八. Our services:

① Our engineers can provide door-to-door service if necessary.

② We will provide test videos and related test standards before delivery.

③ Please confirm that the machine is in good condition and debugged before delivery.

④ We provide a 12-month host warranty.

⑤ The product has passed the quality system and CE certification.

⑥ We provide 24-hour online customer service.

⑦ Provide the material list of wearing parts free of charge.

九, our advantages:

① Our technical team has accumulated 20 years of R&D and production experience in the industry.

② Our after-sales team has 16 years of experience in after-sales service related to screen printing,

so there is no worry about after-sales.

③ We are a manufacturer specializing in the production of high-end screen printing automation

equipment integrating production and sales. We have professional scientific research personnel.

④ We have a dedicated after-sales guarantee service team to solve all problems for you in time.

十, our advantages:

① Our technical team has accumulated 20 years of R&D and production experience in the industry.

② Our after-sales team has 16 years of experience in after-sales service related to screen printing,

so there is no worry about after-sales.

③ We are a manufacturer specializing in the production of high-end screen printing automation

equipment integrating production and sales.We have professional scientific research personnel.

④ We have a dedicated after-sales guarantee service team to solve all problems for you in time.

十一,International Shipping Packing:

十二,After-sales service:

Well maintained, machine has a life of more than 10 years.

Main components are international famous brands,

Our machine operation concept is guaranteed by patent technology.

The whole machine is guaranteed for one year, and the main parts are replaced

free of charge during the warranty period (except for man-made damage and vulnerable parts).

After-sales professional engineers provide technical guidance and and provide lifetime technical support.

On Feb 5th, 2026, we completed a full-load delivery with 13-meter trucks. It is a reassurance to our customers and a testament to our own work. A full-load delivery is not just about weight, but about true significance and responsibility. In 2026, we will continue to deepen our focus and keep moving forward. With a ......

Pioneer in the printing industry,1-6 color on-demand printing, no screen plate, Algorithm-driven, low consumption, less manual work ,Architect of the future printing industry。...

This production line is specially developed and designed for the hot stamping and transfer process of the shell of Yanghe 7th-Generation Haizhilang, featuring an original mechanical + servo positioning structure. The equipment is easy and efficient to operate, which can significantly save labor costs. In addition to b......

JY-202 Double-head high-speed QR code thermal transfer machine Repurchased equipment:It is primarily suitable for transferring onto flat surfaces such as wine caps, cosmetic caps, and similar lids. The transfer speed can reach approximately 80-90 pieces per minute, with a yield rate exceeding 98.5%....

This equipment utilizes a booster cylinder for pressure transmission, a divider turntable for transmission, and fixed fixtures for positioning hot stamping. The hot stamping accuracy can reach 10-15 lines. To change products within the size range, simply replace the fixtures and adjust the corresponding parameters and ......

July 18th, 2025, the star models of JY-121 high-precision side printing production line and JY-215 high-precision side ironing production line of Jingyan were shipped. Thanks to old customers for their trust. These two models are best-selling models independently developed by Jingyan, with super high cost performanc......

On Feb 5th, 2026, we completed a full-load delivery with 13-meter trucks. It is a reassurance to our customers and a testament to our own work. A full-load delivery is not just about weight, but about true significance and responsibility. In 2026, we will continue to deepen our focus and keep moving forward. With a ...

Pioneer in the printing industry,1-6 color on-demand printing, no screen plate, Algorithm-driven, low consumption, less manual work ,Architect of the future printing industry。